Unlocking the Secrets of Bolt Tightening: Your Guide to Torque Specs

Ever wondered how tight is too tight when fastening a bolt? The answer lies within the fascinating world of torque specifications and bolt size charts. These charts aren't just random numbers; they are the key to achieving the perfect clamping force, ensuring your assembled components stay securely in place. Ignoring these values can lead to disastrous consequences, from stripped threads and broken bolts to critical equipment failures.

Proper bolt tightening is crucial across a vast array of applications, from assembling everyday household items to constructing complex machinery and infrastructure. Understanding recommended torque values prevents damage and ensures the long-term reliability of your builds. Imagine a bridge held together by improperly torqued bolts – a terrifying thought, highlighting the critical importance of these seemingly small numbers.

The concept of torque, a rotational force, applied to fasteners has been around for centuries, evolving alongside our understanding of materials science and engineering. Early fasteners relied on experience and "feel," but as technology advanced, so did the need for standardized torque specifications. Bolt size charts emerged as a crucial tool, providing engineers and technicians with the precise values needed for different bolt sizes and materials.

A major issue related to incorrect torque application is the potential for joint failure. Over-tightening a bolt can stretch or even break it, while under-tightening can lead to loosening and eventual separation. Both scenarios compromise the integrity of the assembly and can lead to costly repairs or even catastrophic accidents. This is where understanding bolt torque charts becomes essential.

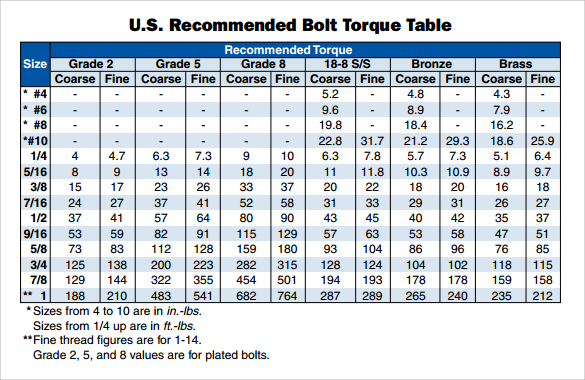

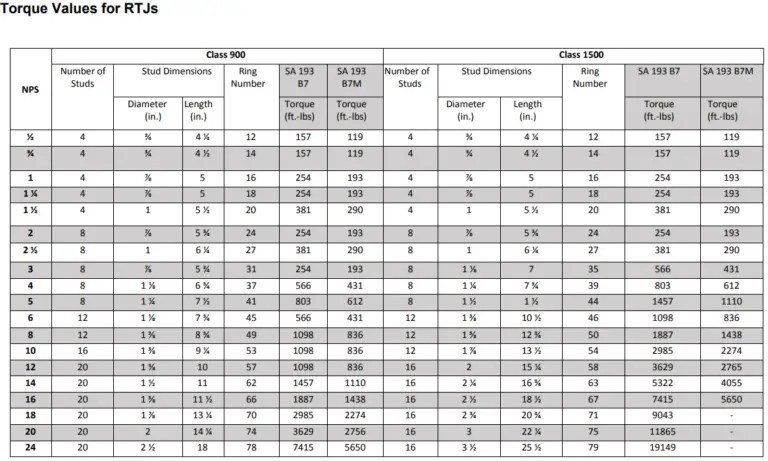

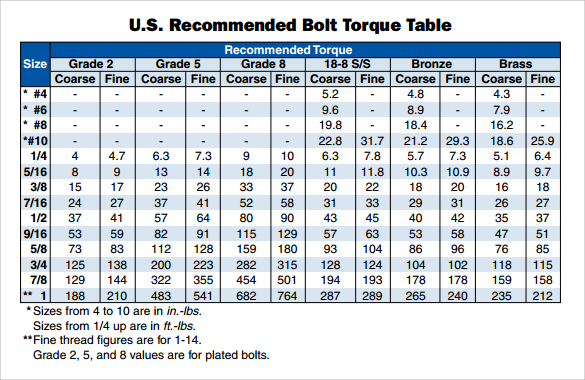

Torque values are typically expressed in units like Newton-meters (Nm) or foot-pounds (ft-lbs). A bolt torque chart provides the recommended torque for a specific bolt size, grade (strength), and material. For example, a common M8 steel bolt might have a recommended torque value of 25 Nm. This means you need to apply a rotational force of 25 Newton-meters to properly tighten the bolt.

One of the primary benefits of using a torque chart is achieving optimal clamping force. This force is what holds the assembled components together, preventing movement or separation. Using the correct torque ensures the clamping force is neither too high nor too low, minimizing the risk of damage and maximizing the joint's strength.

Another advantage is increased safety. Properly torqued bolts are less likely to fail, reducing the risk of accidents caused by component separation. This is especially important in critical applications like automotive and aerospace engineering, where bolt failures can have dire consequences.

Furthermore, using torque charts enhances the longevity of assembled components. By preventing over-tightening, you minimize wear and tear on bolts and the materials they fasten. This can significantly extend the lifespan of your assemblies, reducing maintenance costs and downtime.

To implement correct torque values, you'll need a torque wrench, a tool designed to apply a specific amount of torque. Select the appropriate wrench and socket for your bolt size, adjust the wrench to the desired torque value based on the chart, and then tighten the bolt until the wrench clicks, indicating the target torque has been reached.

Advantages and Disadvantages of Using Torque Charts

| Advantages | Disadvantages |

|---|---|

| Ensures proper clamping force | Requires accurate torque wrenches and proper technique |

| Increases safety and prevents joint failure | Charts can be complex and require careful interpretation |

| Extends the lifespan of components | Different materials and lubricants can affect torque values |

Five best practices for using torque charts:

1. Use a calibrated torque wrench.

2. Clean and lubricate threads.

3. Tighten bolts in a specific sequence.

4. Refer to the correct chart for your specific bolt and material.

5. Double-check critical fasteners.

Five real-world examples:

1. Automotive engine assembly

2. Aircraft wing construction

3. Bridge construction

4. Bicycle assembly

5. Furniture assembly

Five common challenges and solutions:

1. Over-torquing: Use a calibrated torque wrench and follow the chart.

2. Under-torquing: Ensure proper technique and wrench calibration.

3. Stripped threads: Use correct bolt size and avoid cross-threading.

4. Broken bolts: Use the correct torque and ensure proper lubrication.

5. Inconsistent torque: Train personnel on proper torque wrench usage.

FAQs:

1. What is torque? A rotational force.

2. Why are torque charts important? They ensure proper clamping force and prevent failures.

3. What units are used for torque? Nm or ft-lbs.

4. How do I use a torque wrench? Adjust to desired torque and tighten until it clicks.

5. Where can I find torque charts? Online, in manuals, or from manufacturers.

6. What factors affect torque values? Bolt size, grade, material, and lubrication.

7. What happens if I over-torque a bolt? It can stretch or break.

8. What happens if I under-torque a bolt? It can loosen and cause joint failure.

Tips and tricks: Always clean and lubricate threads before tightening. Tighten bolts in a star pattern for even clamping force. Double-check critical fasteners after assembly.

In conclusion, understanding and applying correct torque values using a bolt size chart is fundamental for any assembly task. From preventing catastrophic failures to extending the lifespan of components, the benefits of proper torque control are undeniable. Mastering this skill ensures safer, more reliable, and longer-lasting assemblies. By embracing the principles of torque specifications and incorporating best practices into your work, you elevate your craftsmanship and ensure the integrity of your creations. Don't underestimate the power of these small numbers – they hold the key to successful and enduring builds. Take the time to learn and apply these principles, and you'll reap the rewards of stronger, safer, and more reliable assemblies.

Decoding trailer wheels your guide to the 5 on 5 bolt pattern

Ea sports fc 24 release date speculation and preparation

Dominate your league choosing the top fantasy football defense