Unleashing the Power of Grade 8 Bolt Torque Specs

Ever wonder what holds those monster trucks together? Or how bridges withstand immense pressure? The answer often lies in the humble yet mighty Grade 8 bolt. But it’s not just about the bolt itself; it's about achieving the correct Grade 8 bolt torque. Getting the right Grade 8 bolt tightening values is crucial for safety and structural integrity.

Imagine building a skyscraper with loose bolts. Scary, right? That's why understanding Grade 8 bolt torque requirements is so fundamental. These fasteners are designed for high-stress applications, and improper tightening can lead to catastrophic failures. From construction sites to automotive repair, precise torque application is paramount.

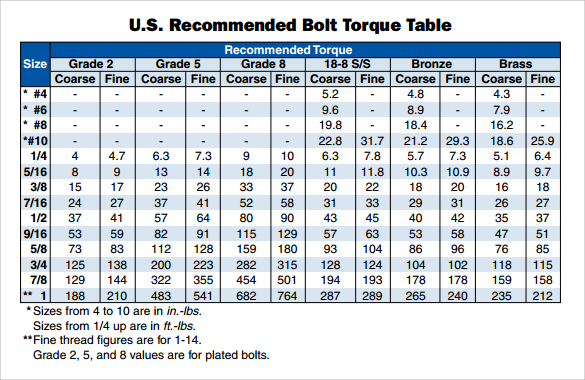

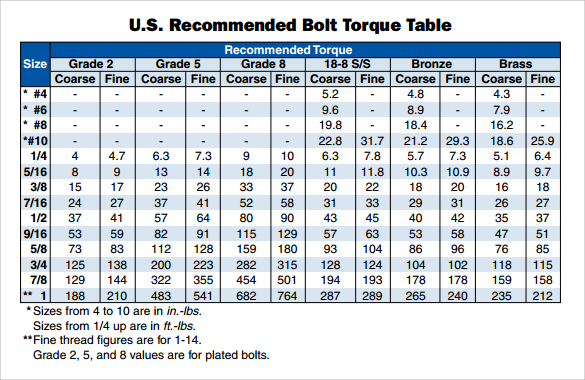

Torque, in simple terms, is rotational force. Think of it like turning a wrench. When dealing with Grade 8 bolts, we’re talking about very specific amounts of this twisting force. These specifications, often expressed in foot-pounds (ft-lbs) or Newton-meters (Nm), ensure the bolt is tightened just enough to hold strong, but not so much that it strips or breaks.

Grade 8 bolts, identified by their six radial lines on the head, are made of high-strength alloy steel, making them ideal for demanding situations. But their strength is only as good as the torque applied. Under-tightening can lead to loosening and joint failure, while over-tightening can damage the bolt or the material it’s fastening. Finding that sweet spot is the key to a secure and reliable connection.

Historically, determining the proper Grade 8 bolt torques involved consulting extensive charts and tables. Today, digital torque wrenches and online resources make the process easier. But the underlying principles remain the same: apply the correct amount of rotational force to achieve the desired clamping force, which holds the joint together. This clamping force is what really matters – it’s the pressure holding the parts together.

One of the main issues related to achieving proper Grade 8 bolt torque is lubrication. Using the wrong lubricant or no lubricant at all can significantly affect the final torque value. A dry bolt will require more torque than a lubricated one to achieve the same clamping force. This is because lubrication reduces friction.

Benefits of proper Grade 8 bolt torques include increased safety, improved reliability, and extended lifespan of the bolted joint. Correctly tightened bolts ensure structures can handle intended loads, preventing accidents and failures.

A simple action plan for applying proper Grade 8 bolt torque involves: 1. Identifying the correct torque specification for the bolt size and material. 2. Selecting the appropriate torque wrench. 3. Preparing the bolt and the mating surfaces. 4. Applying the torque gradually and smoothly. 5. Double-checking the torque value.

Advantages and Disadvantages of Focusing on Grade 8 Bolt Torque Specifications

| Advantages | Disadvantages |

|---|---|

| Increased safety and reliability | Requires specialized tools and knowledge |

| Longer lifespan of bolted joints | Can be time-consuming if done manually for many bolts |

Best practice #1: Always consult the manufacturer's specifications for the correct torque values. Best practice #2: Use a calibrated torque wrench for accurate measurements. Best practice #3: Ensure proper lubrication of the bolt and mating surfaces.

Example 1: Securing a heavy-duty engine mount using Grade 8 bolts and a torque wrench. Example 2: Fastening structural steel beams in a bridge construction project, following precise torque specifications.

Challenge 1: Dealing with rusted or damaged bolts. Solution: Replace the damaged bolts with new ones. Challenge 2: Working in confined spaces with limited access. Solution: Use specialized torque wrenches designed for tight spaces.

FAQ 1: What is the difference between Grade 5 and Grade 8 bolts? Answer: Grade 8 bolts are stronger than Grade 5 bolts. FAQ 2: Can I reuse Grade 8 bolts? Answer: It depends on the application and condition of the bolt. It's generally recommended to replace critical bolts after they've been removed.

Tip: Keep your torque wrench calibrated regularly for accurate readings. Trick: Use a torque marker to visually indicate when a bolt has been properly tightened.

In conclusion, understanding and applying the correct Grade 8 bolt torque specifications is vital for ensuring the safety, reliability, and longevity of any structure or assembly. From massive construction projects to everyday repairs, the principles of proper torque application remain constant. By following best practices, utilizing the right tools, and staying informed about the latest advancements in torque technology, we can harness the full potential of these incredibly strong fasteners. Don't underestimate the importance of that rotational force – it's the key to a strong and lasting connection. Taking the time to understand and apply the correct torque is an investment in safety and performance. So, the next time you see a Grade 8 bolt, remember the power it holds – and the crucial role of torque in unlocking that potential. Remember to consult manufacturer's specifications and use calibrated torque wrenches for every application.

Finding freedom through humility exploring the 7th step in los angeles

Finding your perfect shade sherwin williams color selection

Navigating the college bowl season