Lost Your Timing Marks? Engine Timing Hacks

Engine timing is crucial for optimal performance. But what happens when those vital timing marks vanish? Whether due to wear and tear, a botched repair, or a custom engine build, missing timing marks can feel like a major setback. This guide explores how to establish engine timing even when those crucial guides are absent. We’ll cover various techniques, offer practical advice, and equip you with the knowledge to tackle this challenging situation.

Setting timing without marks isn't a beginner task, but it's achievable with careful attention and the right tools. Before diving in, understanding why timing is so critical is key. Precise timing ensures the engine's valves open and close in harmony with the piston's movement, maximizing power and efficiency. Without it, you risk poor performance, increased fuel consumption, and potential engine damage.

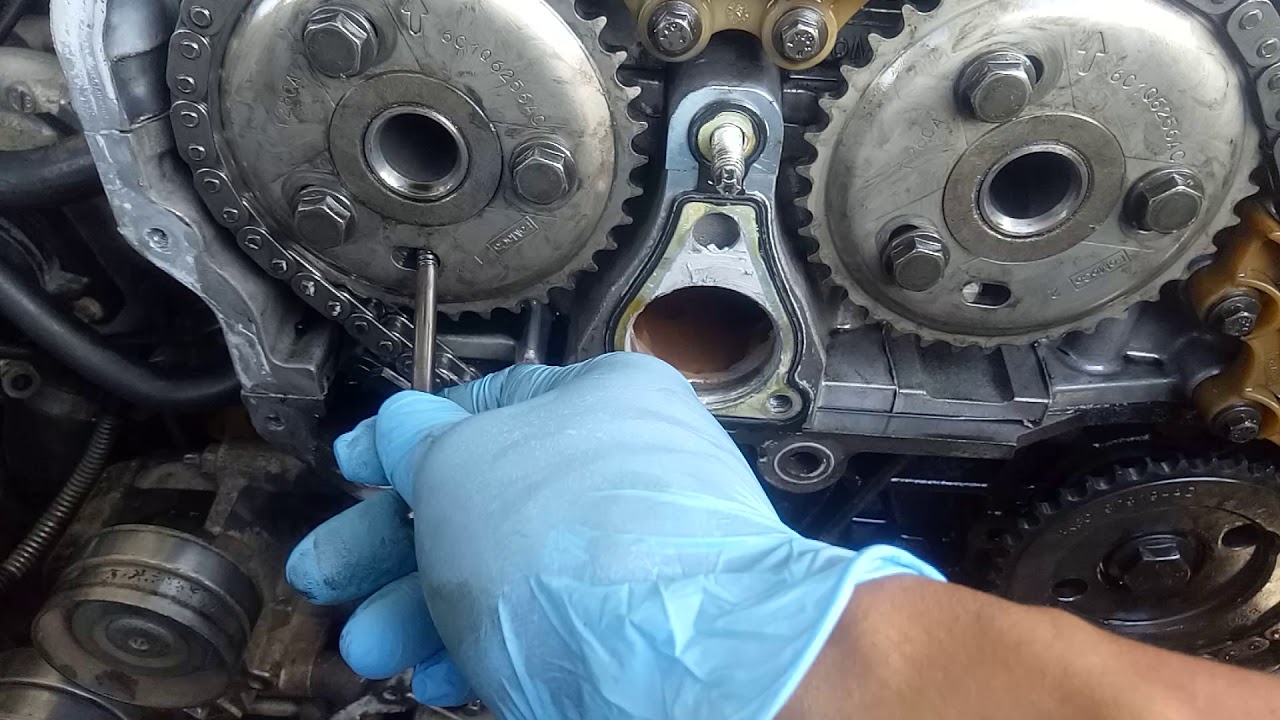

Traditionally, timing marks etched onto the engine components provide a visual reference for aligning the crankshaft and camshaft. These marks simplified the process significantly. Their absence throws a wrench into the works, requiring alternative methods to determine the correct timing. The challenge stems from the need to pinpoint Top Dead Center (TDC) for each cylinder and then synchronize the camshaft accordingly.

Historically, before clearly defined timing marks became standard, mechanics relied on a combination of tools and techniques to set timing. These methods, while more involved, offer valuable solutions when conventional marks are unavailable. Understanding these older practices gives us a foundation for navigating timing adjustments in challenging scenarios.

One of the most common issues encountered when trying to set timing without marks is accurately determining TDC. Without a clear visual indicator, finding the precise point where the piston reaches the top of its stroke can be tricky. This requires careful measurement and observation, and is crucial for ensuring accurate timing. Another common problem is aligning the camshaft correctly once TDC is established. This often involves referencing service manuals and employing specialized tools.

One method involves using a dial indicator to measure piston travel and pinpoint TDC. This tool provides precise measurements, helping you locate the exact top of the piston's stroke. Another technique uses a degree wheel attached to the crankshaft pulley. By rotating the engine and monitoring the degree wheel, you can accurately identify TDC and set the desired timing. For engines with a distributor, static timing can be achieved using a test light to observe the firing point of each cylinder.

Benefit 1: Enhanced troubleshooting skills. Mastering timing without marks deepens your understanding of engine mechanics.

Example: Imagine being able to diagnose a timing issue on a vintage engine lacking clear markings.

Benefit 2: Ability to work on custom or modified engines. Many custom builds omit standard timing marks.

Example: Building a race engine often necessitates custom timing adjustments beyond factory settings.

Benefit 3: Increased self-reliance. You're not dependent on pre-existing marks.

Example: Repairing an engine with damaged timing components becomes manageable even without readily visible marks.Action Plan: Gather your tools (dial indicator, degree wheel, service manual). Determine TDC for cylinder one. Align the camshaft based on engine specifications. Verify timing using a timing light if available. Double-check your work and make necessary adjustments.

Advantages and Disadvantages of Setting Timing Without Marks

| Advantages | Disadvantages |

|---|---|

| Increased understanding of engine operation | More time-consuming process |

| Ability to work on custom engines | Requires specialized tools and knowledge |

| Enhanced problem-solving skills | Higher margin for error |

Best Practice 1: Consult the engine's service manual. This document provides essential timing specifications.

Best Practice 2: Double-check your measurements. Accuracy is paramount when working without visual markers.

Best Practice 3: Use appropriate tools. A dial indicator and degree wheel are invaluable.

Best Practice 4: Take your time. Rushing the process can lead to errors.

Best Practice 5: If unsure, consult a qualified mechanic.FAQ 1: Is setting timing without marks difficult? It's more complex than using marks but achievable with the right tools and knowledge.

FAQ 2: What tools do I need? A dial indicator, degree wheel, and service manual are essential.

FAQ 3: Can I do this without experience? It's recommended to have some mechanical aptitude and experience.

FAQ 4: What if I make a mistake? Incorrect timing can damage the engine, so double-checking is vital.

FAQ 5: Are there any alternatives? If unsure, consulting a professional mechanic is always a good option.

FAQ 6: How do I find TDC without marks? Use a dial indicator or piston stop tool.

FAQ 7: How do I align the camshaft? Refer to the engine's service manual for specific instructions.

FAQ 8: How do I verify the timing? Use a timing light if one is available and applicable to your engine.Tip: Mark your findings as you go. This will help you keep track of your progress and avoid confusion. Trick: Use a piece of wire or a thin rod to feel for TDC through the spark plug hole.

In conclusion, setting engine timing without timing marks presents a unique challenge, demanding a deeper understanding of engine mechanics and precise execution. While the absence of visual guides increases complexity, the techniques outlined above offer viable pathways to success. By utilizing accurate measurements, following best practices, and exercising patience, you can overcome this obstacle and achieve accurate engine timing. The benefits extend beyond simply getting your engine running; they empower you with enhanced troubleshooting skills and the ability to work on diverse engines. Mastering this technique adds a valuable tool to your mechanical repertoire, allowing you to confidently tackle timing adjustments on even the most challenging engines. Don't be discouraged by the lack of marks – with diligence and the right approach, precise engine timing is within your reach. If you're unsure or uncomfortable with the process, consulting a qualified mechanic is always the wisest course of action. Ensuring accurate engine timing is paramount for performance and longevity, so take your time, double-check your work, and enjoy the satisfaction of a well-timed engine.

Augusta wv hardy county arrest records and public information

Unlocking nevada state employment your guide to pay grades and steps

Prepare for birth your guide to childbirth education in san antonio