Effortless Shaft Alignment with Laser Precision

In the realm of machinery maintenance, precision is paramount. A slight misalignment in rotating shafts can lead to a cascade of problems, from energy waste and premature wear to catastrophic equipment failure. Imagine a world where aligning these crucial components is not a complex, time-consuming ordeal, but a streamlined process achievable with a user-friendly tool. Enter the easy laser shaft alignment tool, a game-changer in industrial maintenance.

Shaft alignment, the process of ensuring two or more rotating shafts are precisely aligned, is crucial for the smooth and efficient operation of machinery. Traditional methods often involved cumbersome techniques, requiring significant expertise and time. The easy laser shaft alignment tool simplifies this process, bringing precision and efficiency to the forefront.

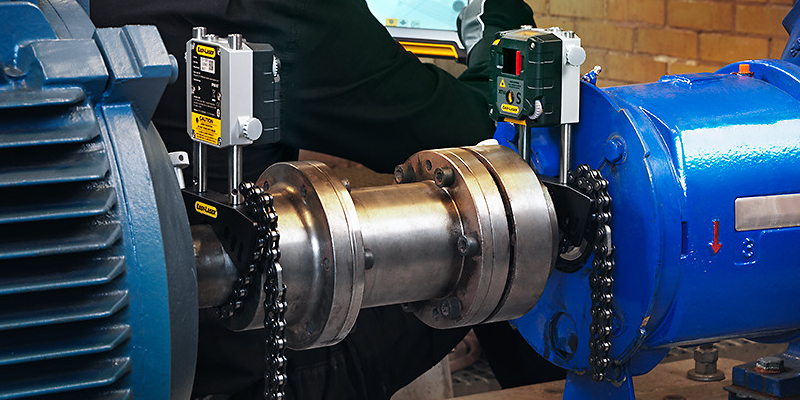

These tools employ laser technology to accurately measure and correct misalignment. By projecting laser beams onto targets mounted on the shafts, the tool calculates the degree and direction of misalignment. This information is then used to guide the user through the necessary adjustments. The simplified interface and clear instructions make these tools accessible to a wider range of users, even those without extensive alignment experience.

Consider the impact of misaligned shafts. Vibrations, excessive heat, and increased energy consumption are just a few of the consequences. These issues can lead to costly repairs, production downtime, and reduced equipment lifespan. An easy laser shaft alignment tool offers a proactive approach to maintenance, preventing these problems before they escalate.

The evolution of shaft alignment tools has seen a dramatic shift from rudimentary methods to the sophisticated laser technology available today. Early techniques relied on dial indicators and straight edges, requiring skilled technicians and considerable patience. The advent of laser technology revolutionized the process, offering unparalleled accuracy and ease of use. Modern easy laser shaft alignment systems provide real-time feedback, guiding users through the alignment process with intuitive displays and clear instructions.

The easy laser shaft alignment tool offers several distinct advantages. First, it significantly reduces the time required for alignment, freeing up valuable maintenance time. Second, it enhances alignment accuracy, leading to improved machine performance and reduced energy consumption. Third, the user-friendly interface makes the tool accessible to a broader range of personnel, reducing the need for specialized training.

To utilize an easy laser shaft alignment tool effectively, follow these steps: mount the laser transmitters and receivers on the shafts, activate the tool and allow it to collect measurement data, and then adjust the machine's alignment based on the tool's instructions. Modern systems often provide visual guidance and step-by-step prompts, simplifying the process further.

One real-world example involves a manufacturing plant that experienced frequent breakdowns due to misaligned pump shafts. After implementing an easy laser shaft alignment tool, the plant saw a significant reduction in downtime and repair costs, along with improved pump efficiency.

Advantages and Disadvantages of Easy Laser Shaft Alignment Tools

| Advantages | Disadvantages |

|---|---|

| Increased Accuracy | Initial Cost |

| Reduced Downtime | Potential for Damage (if mishandled) |

| Ease of Use | Requires Basic Training |

Frequently Asked Questions:

1. What is shaft alignment? - Shaft alignment is the process of ensuring two or more rotating shafts are precisely aligned.

2. Why is shaft alignment important? - Proper shaft alignment minimizes wear and tear, reduces energy consumption, and prevents equipment failure.

3. How does a laser shaft alignment tool work? - It uses laser beams to measure misalignment and guides the user through corrective adjustments.

4. What are the benefits of using an easy laser alignment tool? - Benefits include improved accuracy, reduced downtime, and ease of use.

5. Is specialized training required? - While basic training is recommended, the user-friendly design makes these tools accessible to a wide range of users.

6. How much do these tools cost? - Costs vary depending on features and capabilities.

7. Are there different types of laser alignment tools? - Yes, there are various types designed for different applications and shaft sizes.

8. Where can I purchase an easy laser shaft alignment tool? - These tools are available from specialized industrial suppliers and online retailers.

Tips and tricks: Ensure the shafts are clean and free from obstructions before starting the alignment process. Double-check the mounting of the laser transmitters and receivers to ensure accurate measurements. Follow the tool's instructions carefully for optimal results.

In conclusion, the easy laser shaft alignment tool represents a significant advancement in industrial maintenance. Its ability to simplify a complex process, enhance accuracy, and reduce downtime makes it a valuable asset for any organization reliant on rotating machinery. By investing in this technology, businesses can optimize machine performance, minimize maintenance costs, and extend the lifespan of their equipment. The simplicity of these tools empowers maintenance teams to take a proactive approach, preventing costly breakdowns and ensuring smooth, efficient operations. Embrace the precision and efficiency of laser technology to unlock the full potential of your machinery and maintain a competitive edge in today's demanding industrial landscape. Taking the time to research and select the right easy laser shaft alignment tool for your specific needs is a worthwhile investment that will pay dividends in the long run.

Aews worlds end a deep dive into the trading card phenomenon

Life changing turn manhwa disrupting the digital comics landscape

Unlocking the magic of irish pub music