Decoding Engine Timing: The Secrets of Synchronization

Ever wondered how your engine's internal dance party stays perfectly synchronized? The secret lies within the precisely etched engine timing marks, a roadmap guiding the complex ballet of pistons, valves, and sparks. These markings, often overlooked, are the unsung heroes of smooth, efficient engine operation.

Imagine an orchestra without a conductor. Chaos, right? Engine timing marks serve as the conductor for your engine’s internal combustion symphony, ensuring each component performs its part at precisely the right moment. Without these crucial guides, the engine’s performance would falter, leading to decreased power, fuel inefficiency, and potentially catastrophic damage.

These marks are essentially a visual representation of the engine’s internal timing, allowing mechanics to accurately align critical components like the crankshaft and camshaft. This precise alignment ensures the engine's valves open and close at the correct time in relation to the piston's movement, maximizing power output and minimizing emissions.

Historically, setting engine timing was a complex process involving specialized tools and deep mechanical knowledge. Early automotive engineers painstakingly developed these timing indicators, realizing the vital role synchronization played in engine performance. The evolution of these marks has progressed from simple notches and lines to more sophisticated systems incorporating sensors and computer control.

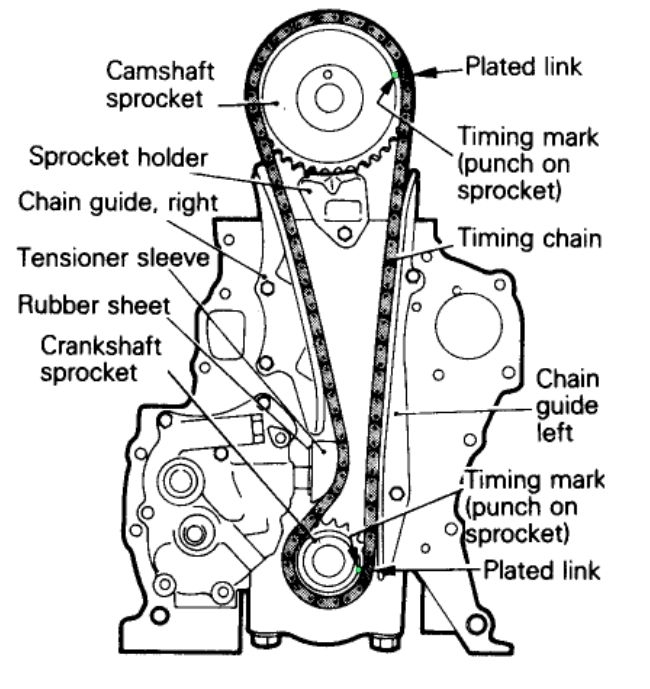

However, even with technological advancements, understanding the fundamental principles of engine timing diagrams remains essential. A timing diagram provides a visual representation of the relationship between the crankshaft and camshaft positions, enabling a mechanic to precisely set the engine's timing according to manufacturer specifications. These diagrams are often found in repair manuals and are indispensable for anyone working on engine internals.

The crankshaft timing marks, usually located on the crankshaft pulley or flywheel, indicate the position of the pistons. The camshaft timing marks, often found on the camshaft sprocket or gear, show the position of the camshafts which control the opening and closing of the valves. Aligning these marks using a timing belt or chain ensures proper synchronization.

One of the primary benefits of accurately set timing is optimized engine performance. When the engine's timing is correctly calibrated, it delivers maximum power and torque, resulting in a more responsive and efficient engine.

Correct timing also contributes significantly to fuel efficiency. A precisely timed engine burns fuel more completely, leading to better mileage and reduced emissions. This not only saves money at the pump but also benefits the environment.

Finally, proper timing helps prevent catastrophic engine damage. Incorrect timing can lead to valve-to-piston contact, a situation where the valves collide with the pistons, causing significant and costly damage.

A typical action plan for setting engine timing involves consulting the vehicle's repair manual for specific timing mark locations and procedures, disabling the ignition system, rotating the engine to top dead center (TDC), aligning the crankshaft and camshaft timing marks, and then installing the timing belt or chain. Verification is crucial after the process is complete.

Troubleshooting timing issues usually begins with checking for obvious signs like a check engine light, rough idling, or loss of power. A diagnostic scan can pinpoint timing-related error codes, guiding the mechanic towards the root cause. Visual inspection of the timing belt or chain for wear or damage is another crucial step.

Advantages and Disadvantages of Understanding Engine Timing Marks Diagrams

| Advantages | Disadvantages |

|---|---|

| Enables accurate engine timing setup | Requires specialized knowledge and tools |

| Optimizes engine performance and fuel efficiency | Can be time-consuming and complex |

| Prevents costly engine damage | Misinterpretation of diagrams can lead to errors |

Best practices include always referring to the vehicle’s specific repair manual, using the correct tools, double-checking the alignment of timing marks, and verifying the timing after completion.

Frequently Asked Questions: What are engine timing marks? Why are they important? Where are they located? How do I find the correct diagram for my engine? What tools do I need? What are the symptoms of incorrect timing? How often should I check my timing belt? What can happen if my timing belt breaks?

Tips and tricks include using a white paint marker to highlight the timing marks for better visibility, ensuring the engine is properly secured before working on it, and taking pictures before disassembly to aid in reassembly.

Understanding the significance of engine timing marks is crucial for maintaining a healthy and efficient engine. From maximizing power and fuel economy to preventing catastrophic failures, these seemingly small markings play a monumental role. By familiarizing yourself with engine timing diagrams, best practices, and troubleshooting techniques, you empower yourself to ensure your engine’s internal symphony plays in perfect harmony. Don't underestimate the power of precise synchronization – it's the key to unlocking your engine’s full potential. Investing time in understanding this fundamental aspect of engine operation is a worthwhile endeavor for any car enthusiast or mechanic, paying dividends in both performance and longevity. Dive deeper into the specifics of your particular engine, consult reputable resources, and empower yourself with the knowledge to keep your engine running smoothly for years to come.

Decoding car battery charger voltage your ultimate guide

Unlocking the power of taupe your guide to sw taupe paint colors

Unlocking the secrets of i am the villain manga chapter 19