Conquering the 6.0 Powerstroke Injector Swap

So, your 6.0 Powerstroke is acting up. Rough idle? Loss of power? Maybe it sounds like a drunken robot trying to tap dance. If so, you might be facing the infamous injector issue. These little devils are known to cause headaches for 6.0 owners, but don't despair. Swapping them out can be a daunting task, but with the right knowledge and preparation, it's totally doable.

Replacing 6.0 Powerstroke injectors is like performing open-heart surgery on your truck. It's a serious undertaking, but necessary for restoring its health and vitality. This isn't a quick fix; it requires patience, precision, and a healthy respect for the power of diesel. But before you dive in head first, let's talk about why these injectors are so important.

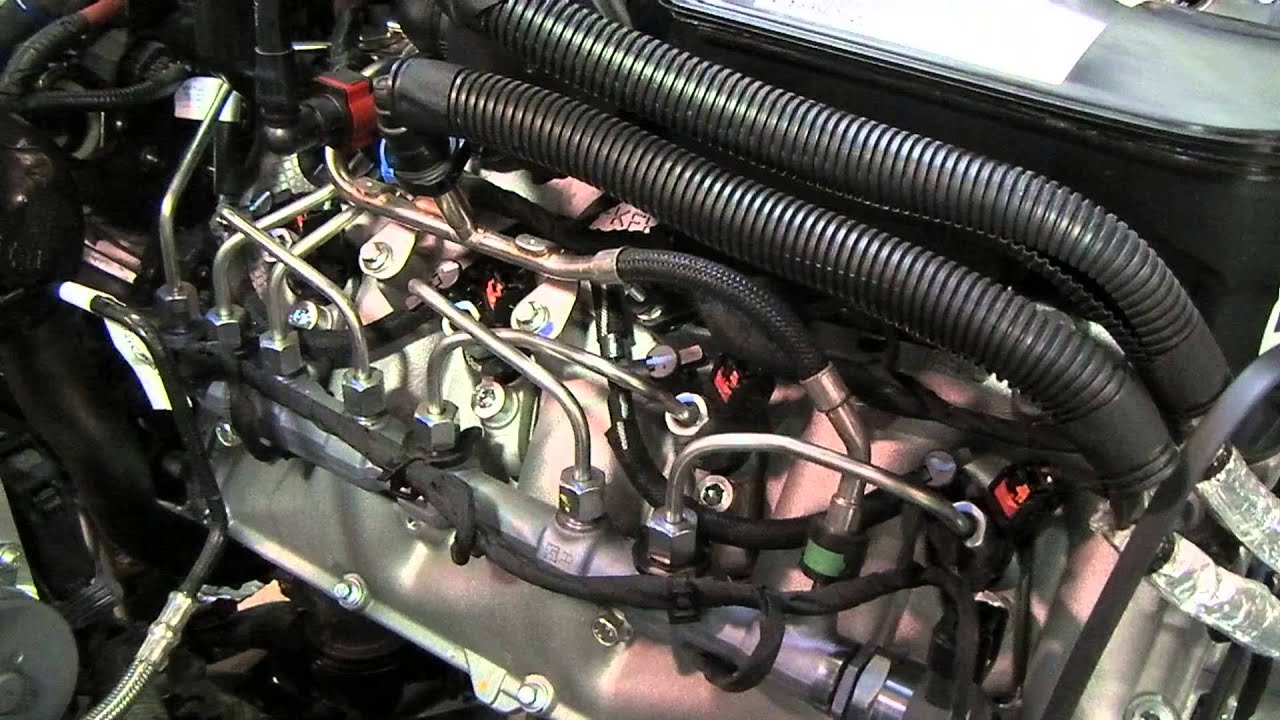

The 6.0 Powerstroke, produced from 2003 to 2007, marked Ford's foray into high-pressure common rail diesel technology. These engines were designed to deliver impressive power and towing capacity, but the early injectors were prone to failure. Over time, improved designs emerged, but understanding the history of these issues is crucial for anyone tackling an injector replacement.

The injectors are responsible for precisely metering fuel into each cylinder. When they malfunction, combustion becomes inefficient, leading to a cascade of problems. This can range from rough running and poor fuel economy to catastrophic engine damage. Replacing faulty injectors not only restores performance but also protects your engine from further harm.

Understanding the function of these injectors is key to a successful replacement. They operate under extremely high pressure, requiring specialized tools and procedures. Imagine tiny, incredibly precise valves opening and closing thousands of times per minute, delivering fuel with pinpoint accuracy. That's the level of engineering we're dealing with here.

One major issue related to 6.0 Powerstroke injector replacement is the potential for complications with the high-pressure oil system. This system is vital for proper injector function, and any disturbance during the replacement process can lead to further problems. Another common issue is stripped or broken injector hold-down bolts, which can be a real nightmare to extract.

Successfully replacing your 6.0 Powerstroke injectors offers several benefits. First, restored engine performance: say goodbye to rough idling and sluggish acceleration. Second, improved fuel economy: faulty injectors waste fuel, so replacing them can save you money at the pump. Third, increased engine longevity: preventing further damage caused by malfunctioning injectors extends the life of your engine.

Creating an action plan is essential for a smooth injector replacement. Gather the necessary tools, including a torque wrench, injector puller, and specialized sockets. Disconnect the batteries and drain the cooling system. Remove the necessary components to access the injectors, such as the valve covers and fuel rails.

Step-by-step instructions are crucial for this complex process. Carefully remove each injector, noting its position and any associated hardware. Install the new injectors, ensuring proper torque specifications are followed. Reconnect all components and refill the cooling system. Finally, prime the fuel system and start the engine.

Advantages and Disadvantages of DIY Injector Replacement

| Advantages | Disadvantages |

|---|---|

| Cost savings compared to professional service | Potential for complications and costly mistakes |

| Sense of accomplishment and increased understanding of your vehicle | Requires specialized tools and significant time investment |

Best practices include using high-quality replacement injectors, meticulously cleaning the injector bores, and carefully following torque specifications. Also, ensure the high-pressure oil system is properly primed before starting the engine.

Frequently Asked Questions: What tools do I need? How long does it take? What are the common mistakes to avoid? Where can I find replacement injectors? What is the torque specification for the injector hold-down bolts? How do I prime the fuel system? What if I break an injector hold-down bolt? How do I know if my injectors are bad?

Tips and tricks: Use a dedicated injector puller to avoid damaging the injector bores. Apply anti-seize compound to the injector hold-down bolts. Double-check all connections before starting the engine.

Replacing the injectors on your 6.0 Powerstroke is a significant undertaking, but it's a rewarding experience that can breathe new life into your truck. By carefully following the proper procedures and taking the necessary precautions, you can successfully conquer this challenge and enjoy the benefits of restored performance, improved fuel economy, and increased engine longevity. Don't let the complexity intimidate you; empower yourself with knowledge and take control of your truck's destiny. The satisfaction of a job well done is worth the effort, and your wallet will thank you in the long run.

Navigating your humana medicare doctor network

Finding solace brotherhood and remembrance

Uefa euro cup streaming on youtube a game changer